Description

Bowtie Engineering delivers systems-based arc flash studies, electrical safety training, and compliance services designed to protect teams and ensure operational uptime. We partner with EHS managers, plant managers, and corporate safety leaders to solve complex electrical safety puzzles—standardizing safety and reliability across facilities. With transparent guidance and tailored risk-reduction strategies, Bowtie helps organizations build an electrical safety culture rooted in real-world expertise.

Reviews

Opening hours

Products And Services

-

Incident Energy Studies

Arc Flash Safety Services and Incident Energy Studies – Bowtie Engineering Bowtie Engineering provides advanced Arc Flash Safety Services and Incident Energy Studies to help companies reduce workplace hazards, protect employees, and maintain full compliance with OSHA and NFPA 70E standards. Every day, arc flash incidents cause severe injuries and claim lives. Most electrical injuries are caused by burns resulting from arc flash explosions that ignite clothing. These risks are real—and preventable. Many organizations implement electrical safety programs, but those programs are often incomplete, poorly maintained, or not aligned with current safety codes. Bowtie Engineering was founded to solve this challenge with a systems-based approach. Our incident energy studies go beyond traditional arc flash reports. We evaluate the unique electrical risks in your facility and implement a structured, six-step process based on NFPA 70E and OSHA 1910 regulations. Each study is performed by a qualified team trained to identify hazards, assess system vulnerabilities, and deliver practical recommendations that support a culture of electrical safety. Through this process, we analyze arc flash risks, evaluate existing conditions, identify required personal protective equipment, and deliver targeted training to your workforce. We also provide equipment labeling and detailed documentation that can be used to update your electrical safety program. In addition, we offer maintenance insights that exceed minimum compliance requirements to support long-term risk reduction. Organizations that partner with Bowtie Engineering gain more than a study—they gain a trusted team committed to improving safety, minimizing downtime, and building resilient operations across every location.

Link: Incident Energy Studies

-

Electrical Maintenance

Electrical Maintenance Services for Operational Continuity – Bowtie Engineering Electrical outages are more than an inconvenience—they are a direct threat to productivity, safety, and long-term asset performance. On average, a typical facility experiences around 100 electrical disturbances each month. These events lead to system downtime, equipment wear, and costly interruptions that often go unmeasured until failure occurs. Bowtie Engineering offers comprehensive Electrical Maintenance Services that give organizations a clear view of their electrical infrastructure and help prevent unplanned outages. Our team of electrical engineering experts performs in-depth system evaluations using advanced tools such as infrared thermography and real-time power monitoring. The result is a detailed Power Quality Report and Analysis that documents current conditions and highlights any risks, inefficiencies, or system deficiencies. Each report includes visual evidence and data-driven insights into key electrical parameters such as voltage levels, current loads, harmonics, and system transients. This information enables facility managers and safety professionals to make informed decisions about upgrades, retrofits, and long-term maintenance strategies. For organizations seeking deeper analysis, Bowtie also performs Energized System Engineering Analysis. This process examines selected electrical distribution components while equipment remains in operation. Services include transformer oil testing, ground resistance checks, voltage drop measurements, and phase balance verification. Customers receive a complete equipment inventory, testing certifications, and documented results—including updated notes on existing one-line electrical drawings when available. With Bowtie’s Electrical Maintenance Services, companies gain the ability to reduce energy waste, extend equipment life, and enhance system reliability. Our findings help teams safeguard personnel, improve operational efficiency, and proactively reduce downtime risk. Every study is tailored to meet the specific needs of your facility and is backed by Bowtie’s commitment to transparency, safety, and system performance.

Link: Electrical Maintenance

-

Energy Solutions

Energy Asset Management Services – Bowtie Engineering The United States consumes significantly more energy than other developed countries, yet operates with lower efficiency. Compared to nations like Japan and Germany, the U.S. uses nearly twice the energy to achieve the same economic output. For businesses, this represents both a challenge and a powerful opportunity to improve profitability through better energy management. Bowtie Engineering delivers strategic Energy Asset Management services that help organizations improve energy efficiency, reduce waste, and lower utility costs without compromising operational performance. These services can function as standalone solutions or as part of Bowtie’s integrated three-part approach to electrical system optimization. Our process begins with a thorough energy analysis performed by licensed engineers with extensive experience in electrical systems, utility billing, and energy efficiency strategies. This analysis examines how energy is used across the facility, what the current energy spend is, and how operating practices affect that usage. We also evaluate utility tariffs, identify energy management opportunities with simple payback, and assess the feasibility of renewable energy sources such as solar or wind. This phase includes recommendations for modernizing outdated equipment and correcting inefficiencies, including options like LED lighting upgrades or power factor improvements for large motor loads. Following the analysis, Bowtie develops a customized Energy Action Plan tailored to your facility’s goals. This plan outlines specific actions to implement cost-saving strategies, establishes data systems for ongoing monitoring, and offers visual tools to support strategic decision-making. It also includes guidance on installing permanent metering infrastructure to enable continuous energy performance improvements. By improving energy efficiency as little as two percent per year over five years, many organizations see a significant return on investment. Bowtie’s expertise ensures every plan is realistic, data-driven, and fully transparent. Our team includes licensed professional engineers and certified energy managers with deep knowledge of utility systems and sub-metering technology. From analysis to implementation, we help businesses build long-term efficiency strategies that support profitability and sustainability.

Link: Energy Solutions

-

EV Systems

EV Charging Systems Testing and Deployment – Bowtie Engineering As the demand for electric vehicles continues to rise, Bowtie Engineering has been a national leader in implementing EV charging infrastructure since 2018. We work with private clients across the country who are taking proactive steps to support the transition to electric mobility and position themselves at the forefront of this shift. Bowtie Engineering provides end-to-end services for electric vehicle charging systems, including site evaluation, engineering design, capacity planning, installation, commissioning, and systems testing. Our team brings a proven background in electrical safety and maintenance, applying those same rigorous standards and principles to the growing EV market. Our approach addresses a critical challenge in EV adoption: many existing electrical systems are not built to support the high-power requirements of EV charging. Every site requires a custom-engineered solution that considers transformer loads, voltage stability, and long-term grid compatibility. Bowtie delivers this level of precision through a standardized process that still allows flexibility based on each client’s needs. As utility providers adjust to this increasing demand, early adopters of EV infrastructure will play a key role in shaping grid resilience. Distributed energy use—like EV charging spread across various locations and timeframes—can actually reduce the likelihood of grid overload and rolling blackouts. Bowtie’s solutions support this transition by helping businesses and institutions install scalable, grid-conscious charging systems. Our experience in critical infrastructure and energy systems makes Bowtie uniquely equipped to guide clients through the complexities of EV integration. From the first consultation to final commissioning, we focus on delivering reliable, compliant, and future-ready charging solutions. Every project reflects our commitment to safety, transparency, and engineering excellence. Let Bowtie Engineering be your trusted partner in developing EV infrastructure that supports your goals while preparing your operations for the demands of tomorrow.

Link: EV Systems

-

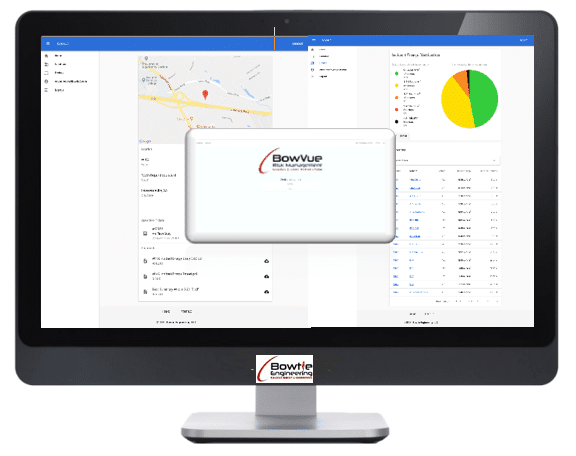

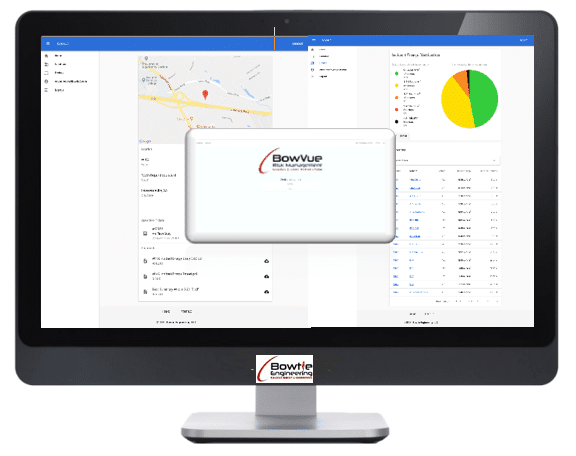

BowVue App

BowVue Electrical Safety App – Bowtie Engineering BowVue is Bowtie Engineering’s proprietary electrical safety app, designed to centralize and simplify oversight of critical electrical systems. Available exclusively to Bowtie clients, this software platform unifies our core services—Incident Energy Studies, Electrical Maintenance, and Energy Solutions—into one intuitive, real-time interface. Developed to support safer, smarter facilities, BowVue allows users to actively manage risk, track compliance, and maintain accurate electrical system data across an entire organization. This platform is available on both desktop and mobile devices, offering clients a clear, on-demand view of their system conditions, service history, and ongoing risk exposure. BowVue enables users to assess maintenance and incident energy risk through its built-in pre-task planning tool. It supports decision-making with detailed documentation at the asset level, including cal/cm² values, system inventories, and service reports. Users can review current conditions, identify personnel training needs, confirm PPE availability, and track system changes—all from a single, secure dashboard. With access to Bowtie’s secure cloud server, organizations can store, retrieve, and manage their electrical safety data with confidence. The BowVue app helps ensure compliance with OSHA and NFPA 70E standards while reducing the risk of failed audits and unplanned equipment failures. By combining expert engineering with cutting-edge software, Bowtie Engineering delivers an unmatched level of control and clarity for managing electrical system safety across every location.

Link: BowVue App

-

NFPA 70E Training

NFPA 70E Electrical Safety Training – Bowtie Engineering Electrical injuries remain one of the most serious risks in industrial environments, with a severe incident occurring approximately every 30 minutes. Arc flashes, electrical shock, and equipment-related hazards can lead to life-altering injuries, including burns, hearing loss, and vision damage. These incidents are preventable when workers are properly trained and systems are aligned with current safety standards. Bowtie Engineering delivers comprehensive NFPA 70E training programs that help employers protect their teams, ensure regulatory compliance, and build a lasting culture of safety. Developed to reflect the most current NFPA 70E standard and OSHA 1910 requirements, our training prepares employees to recognize risks and apply best practices when working with energized systems. We offer both online and in-person instruction led by experienced trainers with deep knowledge of field applications and electrical safety protocols. This training goes beyond theory, incorporating real-world scenarios and operational risk assessment to make the material relevant and immediately applicable. Workers gain the knowledge needed to justify job tasks, understand hazard boundaries, assess arc flash risks, and perform duties with confidence and control. Our in-person training includes a full eight-hour on-site session designed for up to 25 participants. This structured experience covers topics such as lockout/tagout procedures, maintenance safety, arc flash awareness, and hands-on risk evaluation practices. Every session is built to not only meet compliance standards but also reduce the likelihood of workplace injuries and costly downtime. With Bowtie’s electrical safety training, your team is empowered to make safer decisions and your organization benefits from lower liability, improved safety culture, and stronger alignment with industry standards.

Link: NFPA 70E Training

Categories

General Contractors(414)315-4868 (414)-315-4868 +14143154868 (866)730-6620 (866)-730-6620 +18667306620

Map 1400 Market Place Boulevard

Loading map...